In the field of injection molding, especially injection molding auto parts,PA66, and PA6 play an important role. But most of the time auto parts manufacturers are looking for glass fiber reinforced modified PA6 and PA66. These materials are collectively referred to as GRP or FRP, or glass fiber reinforced plastics.It is sturdy, very light and highly flexible. The properties of FRP are different from traditional thermoplastics used in everyday products. This means that GRP/FRP has properties that are common to multiple industries.

FRP/GRP, is a composite material formed by a fiber-reinforced polymer matrix.While the fibers used are usually glass fibers such as GRP, others, such as carbon, aramid or basalt are also used. FRP is a broader generic term commonly used for engineering materials in a wide range of industrial applications. However, when referring to FRP, the term FRP is often used interchangeably.

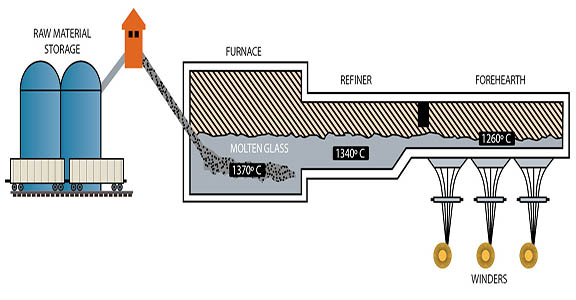

Fiberglass is made of fiberglass. These are very fine fibers that are woven together to create a soft fabric. A GRP is a molded product, which means it must be placed in or around an item of the desired shape. GRP composites incorporate an alumina aggregate surface, which is diamond hard and provides high long-term wear resistance.

For GripClad products, non-slip grit cannot be removed like overcoating methods. There will be no peeling or chipping around the localized damage point, the color will not wear off, and bending/moving will not have any effect. For GRP and FRP materials, it is 100% guaranteed not to rust or corrode.

These products are pre-fabricated and the plate/cover to which they can be installed is made of very strong composite fiberglass. All of our products are held together in a single manufacturing process, sometimes referred to as pultrusion, and are the strongest and most durable pedestrian safety products available today.

GRP gratings are produced by the moulding method, while GRP handrails and pultruded profiles are produced by the pultrusion method. GRP stair tread covers, GRP panels and GRP stair leading edges are made from a basic blend of flame retardant polyester resins interspersed with layers of extremely strong interwoven fiberglass. Pigmentation floats through the entire thickness of the material, so the color is unlikely to fade and become unsightly. Then, under pressure, press the fused alumina skid pellets into the base mix while keeping it wet, and then lay a final coat of resin on top of it. The entire composite mix is then cured at the optimum temperature until fully hardened. No delamination, no bonding, no weakness, just a very strong composite solid product.

Fiberglass has many valuable properties and is very useful in industries around the world. These properties include: heat insulation, non-slip safety, high strength to weight ratio. Does not melt, but burns like wood (can produce flame retardant if desired), high energy absorption, chemical resistance, corrosion resistance, good thermal and sound insulation performance, easy to shape. Fiberglass is a useful material for a variety of reasons. No matter what your application is, or what industry you are in, GRP is a durable and reliable product.

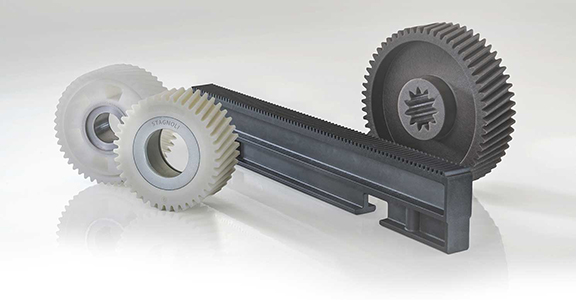

Fiberglass is used in a variety of different applications. Products made partly or entirely of FRP have uses in many industries. Eg: mains or drain cover, anti-slip protection for refurbished wet and dry floors, helicopter rotor blades and wind turbine blades, armrest, electronic enclosure, Security grilles in industrial and public areas, Sports equipment such as kayaks. FRP is a popular and reliable product due to its versatility. For more industry-specific information on GRP use, check out our industry pages for more information on how we use GRP.

The applications of GRP materials and composites vary, but can be used for building reinforcement. Fiberglass reinforced plastic (GRP) can be used in a variety of environments, from residential and commercial to the educational sector. GRP composites are popular for their reinforcing properties, and there are a number of secondary benefits to using GRP composites in construction: corrosion resistance, corrosion resistance, chemical resistance, persistent, non-conductive material.

Dema commits to create value for our clients, provide solutions of polymer raw materials, like PP, PE, PVC, PET, ABS and FIBC bags, and help you occupied a competitive position in your market. You are welcome to contact us at any time, we will serve you wholeheartedly.