1. Linear Low density polyethylene (LLDPE)

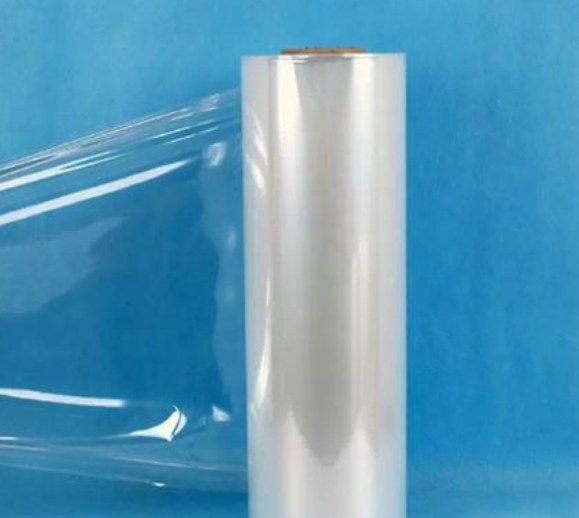

Linear Low density polyethylene (LLDPE) is a type of polyethylene that is synthesized by a low pressure catalyst. Compared with traditional low-density polyethylene (LDPE), LLDPE has a higher molecular structure with higher crystallinity and a narrower molecular weight distribution, so it has better tensile property, impact resistance and stronger thermal stability. This excellent performance of LLDPE makes it an indispensable component in packaging materials, especially in the production of thin film materials.

2. Application of LLDPE in packaging industry

2.1 Food Packaging

LLPE has a wide range of applications in food packaging, mainly for the production of various types of packaging films, including food bags, cling film and multilayer packaging materials. The flexibility and transparency of LLDPE make it ideal for packaging fresh foods, snacks, frozen foods and more. In addition, LLDPE film has good waterproof and oil-proof properties, which can effectively extend the freshness life of food.

2.2 Industrial Packaging

LLDPE is also widely used in industrial packaging, especially in the production of large cargo packaging film, pallet packaging film, stretch film and other products. LLDPE has high tensile strength and puncture resistance, which can effectively protect the product from external damage. In addition, LLDPE film material has good ductility, can wrap a variety of irregularly shaped objects, improve packaging efficiency.

2.3 Agricultural Packaging

In the agricultural field, LLDPE is widely used in the production of agricultural film, agricultural film and so on. Its excellent UV resistance, anti-aging properties and high transparency make LLDPE the preferred material for greenhouse, mulch, sunshade and other products. These applications can improve the growing environment of crops and promote agricultural production efficiency.

2.4 Medical Packaging

The application of LLDPE in medical packaging is also gradually increasing, especially in aseptic packaging, pharmaceutical packaging and disposable medical supplies packaging. Its transparency, non-toxicity and good barrier properties make it an important packaging material for the medical industry.

3. The development trend of LLDPE in packaging industry

3.1 Combination of environmental protection and biodegradable technology

At present, there are many methods to improve the recovery and degradation of LLDPE. For example, by developing degradable LLDPE materials or combining them with bio-based polymers to produce more environmentally friendly packaging materials, it has become an important development direction for the packaging industry.

3.2 Functionalization and intelligent packaging

In the future, functional and intelligent packaging will become the development trend of the packaging industry. LLDPE, as a multi-functional base material, can enhance its antibacterial, anti-ultraviolet, anti-static properties by adding different functional fillers or modifiers. In addition, with the increasing demand for smart packaging due to the application of Internet of Things (IoT) technology, the potential of LLDPE in smart packaging will be further developed.

3.3 Thinner and lighter packaging materials

With the increasing demand of consumers for convenience and environmental protection, the trend of lightweight and film packaging is becoming more and more obvious. The adjustable thickness characteristics of LLDPE enable it to meet this demand by improving the production process to make thinner and lighter packaging materials while maintaining their superior performance.

3.4 Application of nanotechnology

With the continuous development of nanotechnology, the application of nano-fillers has gradually penetrated into plastic packaging materials. Adding nanoparticles (such as nano-oxides, nano-fibers, etc.) to LLDPE can not only improve its mechanical strength, but also give the packaging film better moisture resistance, antibacterial, anti-ultraviolet and other functions. In addition, nanotechnology can also improve the breathability and barrier properties of LLDPE, further improving the functionality and adaptability of packaging materials.

Conclusion

Linear low density polyethylene (LLDPE) as an important packaging material, with its excellent performance and wide application prospects, occupies a pivotal position in the packaging industry. With the increasingly strict environmental regulations and continuous innovation of technology, LLDPE packaging materials will develop in the direction of environmental protection, functional, intelligent and lightweight. In the future, with the continuous progress of technology, LLDPE's position in the packaging industry will be more stable, but at the same time, it also needs to meet the challenges of environmental protection, resource recycling and other aspects.

About Us

Luoyang Dema Import & Export Co., Ltd. aims to provide high-quality, cost-effective products for global factories, plastic product manufacturers, and material distributors. Luoyang Dema Import & Export Co., Ltd. provides the best PP, PE, PVC, AVE, and ABS material solutions for plastic product manufacturers, wholesalers, distributors, distributors, factory owners, processing workshops, etc.

If you are looking for general plastic materials, please feel free to get the latest prices and quotations from Luoyang Dema Import & Export Co., Ltd. The sales team will reply within 48 hours.