The roles of structures of FIBC bags?

Bulk tapes both protect the product and facilitate loading, unloading and storage. Therefore, bulk tape is an economical and flexible shipping package for many products. But the production process of bulk bags is not a simple matter. Because the production process involves a variety of filling methods, storage methods, loading and unloading methods, and different application fields, it is very important to communicate with the manufacturers of bulk bags. Now let's talk about the structure classification of bags, in order to get a more accurate quotation from the bulk belt manufacturer.

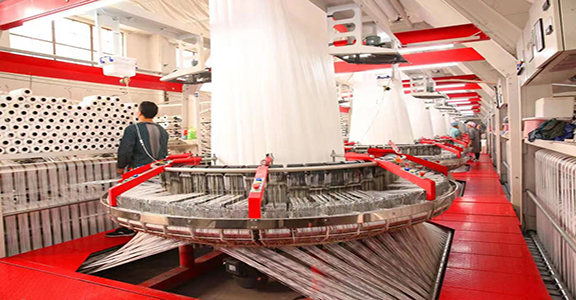

Circular woven FIBC bags:

A circular or tubular bag is a circular or tubular polypropylene base fabric woven with a circular loom, and then cut to the required size.Despite having a square top and bottom sewn to the bag, round woven bags still have a round/cylindrical filling. One advantage of a round woven bag is that it requires the least amount of stitches (top and bottom only). Possible downside: they don't hold their shape like other styles of bags.

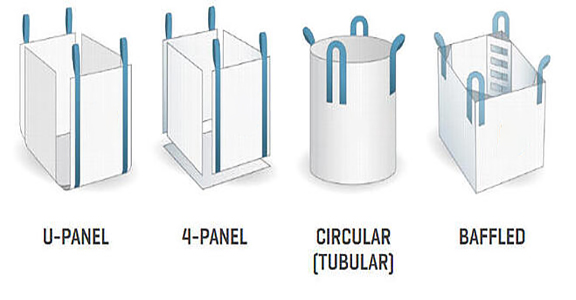

U-Panel FIBC bags

Consists of three panels. One panel runs the entire length of the bag, forming a U, creating the bottom and two sides. The other two panels are sewn into the U shape to form the other two sides. The u-panel bag stays square when filled, especially if it has baffles.

Four panel FIBC bags

It is an original polypropylene design, Four Panel Bulk Bags (FIBCs) with fabric separated along four seams, sewn together to construct the body of the bag as well as to stitch the top and bottom together. Four-board bags hold their shape better than other types of bags for stacking.

Conical FIBC bags

Cone bags are specially designed to help drain the contents completely, such as brown sugar and premixed flour products. The conical shape of the bottom of the bag ensures quick and easy discharge of bulk bags.

Baffle FIBC bags

Effective use of the storage capacity of the bag. Four rigid cross corner rings allow forklifts operators can pick up luggage without the need for additional staff. The baffle bag is ideal for light density products and can be more economical because it increases payload - larger panel widths allow 25%-30% more product in the corners. Another advantage is the increased stackability and the turning of all stitched edges to the outside, which reduces the potential for contamination.

The bulk bag factory can accurately determine the processing cost according to these four structures, and it is easy to reveal the price, so for the user, knowing these structures can save the bag cost and transportation cost, and allow the factory to accurately understand your need.

As a professional FIBC bag manufacturer, we provide you with professional flxeible intermediate container solutions. At the same time, we also provide FIBC bag manufacturers with polypropylene raw materials, polypropylene textile fabrics and other bulk bag related materials. Dema Import and Export will provide you with cost-effective jumbo bag and PP woven sacks with first-class quality and service. Welcome your inquiry.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.