When choosing materials for water supply lines, two commonly considered options are PE (Polyethylene) and PVC (Polyvinyl Chloride). Both materials are widely used in plumbing and infrastructure applications due to their durability, affordability, and adaptability. This article explores whether PE or PVC is suitable for water supply lines by examining their characteristics, advantages, and ideal applications.

Overview of PE and PVC

What is PE?

Polyethylene (PE) is a versatile thermoplastic polymer known for its flexibility, chemical resistance, and toughness. It is available in various forms, such as high-density polyethylene (HDPE) and cross-linked polyethylene (PEX). These variants are widely used in water supply systems, gas lines, and industrial piping.

What is PVC?

Polyvinyl Chloride (PVC) is another thermoplastic polymer that has been a staple in plumbing for decades. It is recognized for its rigidity, chemical resistance, and cost-effectiveness. PVC pipes are commonly used for drainage systems, cold-water supply lines, and irrigation.

Key Properties for Water Supply Lines

When evaluating materials for water supply lines, several critical factors must be considered:

Pressure Resistance: The material must withstand high water pressure without deforming or bursting.

Temperature Tolerance: The ability to handle both cold and hot water is essential for many plumbing applications.

Chemical Resistance: Resistance to corrosion and reactions with chemicals in water ensures longevity.

Durability: The material should resist wear, environmental stress, and long-term degradation.

Potable Water Safety: For drinking water, the material must comply with safety standards and not leach harmful substances.

Can PE Be Used for Water Supply Lines?

Benefits of PE

Flexibility: PE pipes, especially HDPE and PEX, are highly flexible, allowing them to be bent around obstacles without requiring many fittings. This reduces installation time and costs.

Corrosion Resistance: PE is highly resistant to corrosion and chemical reactions, making it ideal for long-term use in water supply systems.

Durability: PE pipes can withstand external pressures and environmental stress, such as soil movement or earthquakes.

Temperature Tolerance: Certain types of PE, such as PEX, are designed for both cold and hot water applications. PEX can handle temperatures up to 200°F (93°C).

Potable Water Certification: Many PE pipes are certified safe for potable water, ensuring no harmful chemicals are released into the water supply.

Ease of Installation: PE’s lightweight and flexibility make it easy to transport and install, even in challenging environments.

Limitations of PE

UV Sensitivity: PE pipes are sensitive to ultraviolet (UV) light. Prolonged exposure to sunlight can degrade the material, necessitating proper burial or shielding.

Pressure Rating: While HDPE can handle high pressures, not all types of PE are suitable for high-pressure systems. It’s essential to verify the specific pressure rating of the chosen PE pipe.

PE, particularly HDPE and PEX, is an excellent choice for water supply lines due to its flexibility, durability, and safety for potable water.

Can PVC Be Used for Water Supply Lines?

Benefits of PVC

Affordability: PVC is one of the most cost-effective materials for water supply lines, making it a popular choice for large-scale projects.

Chemical Resistance: PVC is resistant to a wide range of chemicals, ensuring longevity in diverse water conditions.

Pressure Handling: PVC pipes are available in various pressure ratings, allowing them to be used in different types of water supply systems.

Lightweight: PVC’s lightweight nature simplifies transportation and installation, reducing labor costs.

Potable Water Safety: NSF-certified PVC pipes are approved for potable water applications, ensuring safe water delivery.

Rigid Structure: PVC pipes have a rigid structure, which provides stability in underground installations.

Limitations of PVC

Temperature Sensitivity: Standard PVC is not suitable for hot water applications as it softens at higher temperatures. For hot water systems, CPVC (Chlorinated Polyvinyl Chloride) is required.

Brittleness in Extreme Cold: PVC can become brittle in extremely cold temperatures, which may lead to cracking or failure under stress.

Priming Requirement: PVC pipes often require priming before solvent cement is applied, adding an extra step to the installation process.

Environmental Concerns: The production and disposal of PVC raise environmental concerns due to the release of harmful chemicals.

PVC is a reliable option for cold water supply lines, especially in residential and irrigation systems. However, it is not suitable for hot water applications unless CPVC is used.

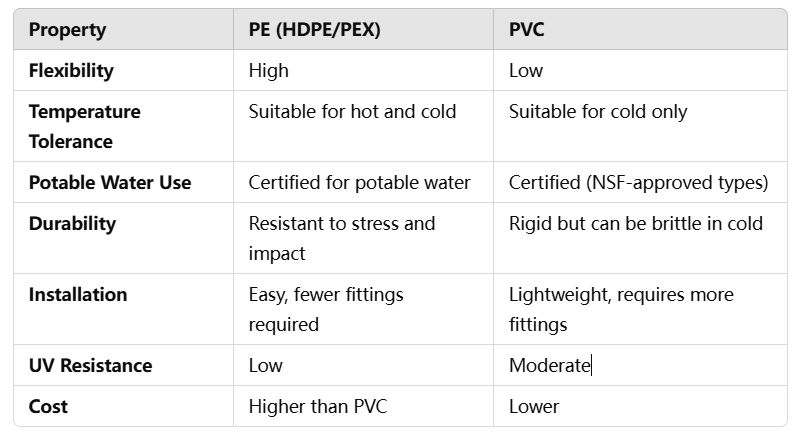

PE vs. PVC: A Comparison

About Us

Luoyang Dema Import & Export Co., Ltd. aims to provide high-quality, cost-effective products for global factories, plastic product manufacturers, and material distributors. Luoyang Dema Import & Export Co., Ltd. provides THEbest PP, PE, PVC, AVE, ABS material solutions for plastic product manufacturers, wholesalers, distributors, distributors, factory owners, processing workshops, etc.

If you are looking for general plastic materials, please feel free to get the latest prices and quotations from Luoyang Dema Import & Export Co., Ltd. The sales team will reply within 48 hours.