Introduction of polyethylene

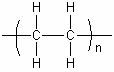

Polyethylene or polyethene is athermoplastic polymer

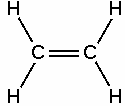

Basic monomer unit is ethen

Polyethylene classification

| Designation | Acronym | Density g/cc |

| High Density Polyethylene | HDPE | >0.941 |

| Low Density polyethylene | LDPE | 0.910~0.941 |

| Linear Low density polyethylene | LLDPE | 0.915~0.925 |

| Ultra High Molecular Weight Polyethylene | UHMWPE | 0.930~0.935 |

Comparison of properties of polyethylene

| Properties | LDPE | HDPE | LLDPE | UHMWPE |

| Molecular mass | 87000 | 96000 | 96000 | 4.5X106 |

| Yield strength MPa | 12.4 | 26.5 | 10.3 | 22 |

| Reputure srtength MPa | 12 | 21.1 | 25.3 | 44 |

| Impact energy KJ/m2 | 61 | 5 | 63 | 210 |

Polyethylene application area

LDPE

Film for food packaging

Sealants and insulators

Adhesives

Carry out bags Squeeze bottles molded laboratory equipment

HDPE

Water pipes

Containers (milk, laundry detergent etc.)

Electrical wire insulation

Other plastics packaging (caps, trays etc.)

Trash Bags

Industrial drums

LLDPE

Plastic bags and sheets (where it allows using Lower thickness than comparable LDPE) Plastic wrap

Flexible tubing

Toys

Buckets and containers

UHMWPE

High modulus fibers for bulletproof vests

Orthopedic implants (artificial hips, knees)

Due to its low friction and wear resistance it is

used in industrial impact, wear, and sliding

applications in both normal and corrosive

environment

Coatings for grain silos

PROPERTY | METRIC | UNITS | ENGLISH | UNITS |

General | ||||

Density | 952 - 965 | kg/m^3 | 00.344 - 0.0349 | lb/ft^3 |

Mechanical | ||||

Yield Strength | 2.62e7 - 3.1e7 | Pa | 3.8 - 4.5 | ksi |

Tensile Strength | 2.21e7 - 3.1e7 | Pa | 3.21 - 4.5 | ksi |

Elongation | 11.2 - 12.9 | % strain | 1.12e3 - 1.29e3 | % strain |

Hardness (Vickers) | 7.75e7 - 9.71e7 | Pa | 7.9 - 9.9 | HV |

Impact Strength (un-notched) | 1.9e5 - 2e5 | J/m^2 | 90.4 - 95.2 | ft.lbf/in^2 |

Fracture Toughness | 1.52e6 - 1.82e6 | Pa/m^0.5 | 1.38 - 1.66 | ksi/in^0.5 |

Young's Modulus | 1.07e9 - 1.09e9 | Pa | 0.155 - 0.158 | 10^6 psi |

Thermal | ||||

Max Service Temperature | 113 - 129 | °C | 235 - 264 | °F |

Melting Temperature | 130 - 137 | °C | 266 - 279 | °F |

Insulator or Conductor | Insulator | Insulator | ||

Specific Heat Capability | 1.75e3 - 1.81e3 | J/kg °C | 0.418 - 0.432 | BTU/lb. °F |

Thermal Expansion Coefficient | 1.06e-4 - 1.98e-4 | strain/°C | 59 - 110 | µstrain/°F |

Eco | ||||

CO2 Footprint | 1.95 - 2.15 | kg/kg | 1.95 - 2.15 | lb/lb |

Recyclable | Yes | Yes | ||